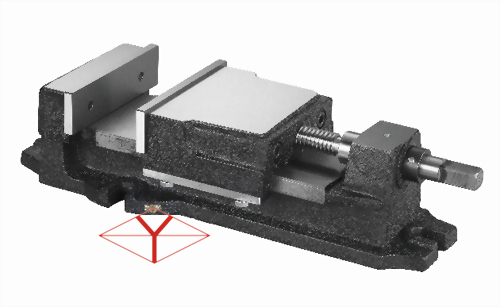

CNC PREICISION MACHINE VISE -MV

MV - CNC PREICISION MACHINE VISE

|

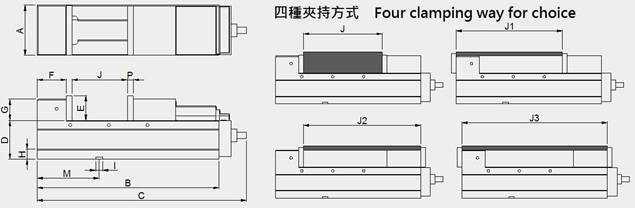

MODEL |

A |

B |

C |

D |

E |

F |

G |

H |

I |

M |

P |

J |

J1 |

J2 |

J3 |

重量 KG |

|

MV-100A |

100 |

395 |

485 |

85 |

53 |

60 |

50 |

25 |

18 |

110 |

15 |

200 |

270 |

310 |

380 |

26 |

|

MV-130A |

130 |

470 |

560 |

100 |

58 |

75 |

55 |

25 |

18 |

160 |

15 |

250 |

330 |

360 |

450 |

44 |

|

MV-160A |

160 |

545 |

635 |

100 |

63 |

80 |

60 |

25 |

18 |

200 |

18 |

300 |

380 |

420 |

520 |

63 |

|

MV-160S |

160 |

488 |

580 |

100 |

63 |

80 |

60 |

25 |

18 |

200 |

18 |

250 |

340 |

380 |

470 |

57 |

|

MV-200A |

200 |

605 |

695 |

110 |

63 |

95 |

60 |

25 |

18 |

220 |

18 |

340 |

460 |

490 |

600 |

84 |

Features:

Ø present vise each track by precision machining and polishing process for Li / precision machining of the machining center Integrated milling cutting horizontal use.

Ø vise body of high ductility materials used spheroidal graphite cast iron (FCD600) is integrally molded design, this station via the sliding surface hardening heat treatment (of HRC50 [deg.]) , To ensure high-precision, high wear resistance, high tensile strength.

Ø jaw heat treatment hardness of HRC55 [deg.] .

Ø Angle-fixed semi-circular ball can generate the force of corner-fixing and locking, which can eliminate the floating of the workpiece.

Ø This clamping vise can be used in four different ways.

Ø present vise with anti chip design prevents iron easily discharged into the interior of the internal and vise vise and prolong life.

Ø body height of the vise given Jie-inch size ( D ), more than one can be used simultaneously.